Shandong Gelon Lib Co., Ltd

Gelon Teams since 2003 engaged in battery business,Enterprises from

the initial Ni-MH battery production extends to the production of

lithium ion battery materials and battery . Most of the senior

management staffs graduated from China's most famous

electrochemical professional --CENTRAL SOUTH UNIVERSITY, from which

created a lot of leaders in Chinese lithium ion battery industry

such as Mr ChuanFu Wang(BYD),Mr XinDe Xia, Mr KaiHua Xu, Professor

GuoRong Hu and XinHai Li Etc. Owning a group of experienced

engineers and staffs, we can bring you not only reliable products

and technology, but also excellent services and real value you will

expect and enjoy. Gelon Focus on manufacturing and selling of new

materials (anode, cathode, separator, additive etc. ) for lithium

ion battery, and also offer full sets of materials solution to

customers. Our preponderant products are Lithium Iron

Phosphate(LFP), Lithium Manganese Dioxide(LMO), Lithium Cobalt

Oxide(LCO), Lithium Nickel Manganese Cobalt Oxide(NMC), Lithium

Nickel Aluminum Oxide(NCA) ,Lithium Titanate Oxide(LTO) materials;

Graphite materials (MCMB) , Separator & Other accessories (SBR CMC

NMP PVDF,Sup-Li,Al&Ni Tabs )etc for new power lithium ion

batteries. Meanwhile, we have our own lithium ion battery factory

who mainly produces lithium ion battery for camera, mobile, EV

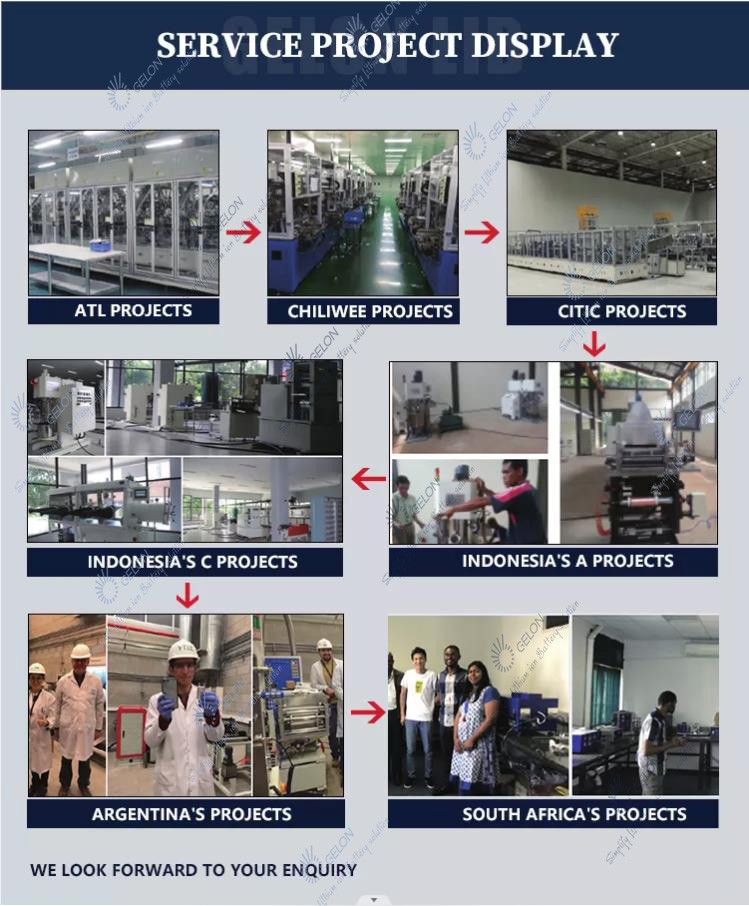

application. Based on our battery production line, we can offer all

services (Raw Materials, Equipments, Production line design

&Technology, etc. ) for full set of equipments to help clients

to set up Lab & Pilot line for lithium ion battery. Bynow, Gelon

have finished many turn key project in Bolivia,Indonesia, Indian,

Russia,Turkey and South Africa We have a more than ten years

professional and experienced exporting teams to supply perfect

services for all our customers. We are confident on our quality and

service.And ensure to offer the best services based on our

specialty and empressement. Our Aim is to be the comprehensive

company dealing with One-Stop services for Lithium ion battery in

the world. Our Business Philosophy: You choose us, We promise you

What we offer to you,are what we are using Integrating the quality

resources in China, delivering the best service and products to

you. The best product we can provide, is our sincerity and

reliability.